To get best possible properties for spoke wire, it is very important to fulfill following parameters:

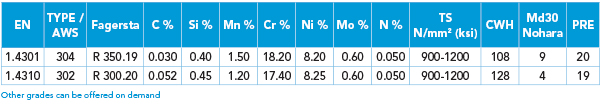

We recommend following standard grades:

EN | TYPE / AWS | Fagersta | C % | Si % | Mn % | Cr % | Ni % | Mo % | N % | TS Nmm2 (ksi) | CWH | Md30 Nohara | PRE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1.4301 | 304 | R 350.19 | 0.030 | 0.40 | 1.50 | 18.20 | 8.20 | 0.60 | 0.050 | 900-1200 | 108 | 9 | 20 |

1.4310 | 302 | R 300.20 | 0.052 | 0.45 | 1.20 | 17.40 | 8.25 | 0.60 | 0.050 | 900-1200 | 128 | 4 | 19 |

Other grades can be offered on demand

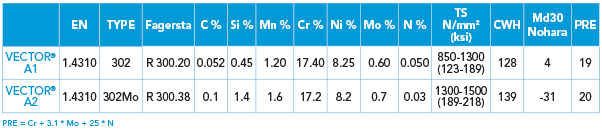

Our high-end spoke wire for racing and downhill bicycles. Vector® is our austenitic spoke wire collection. It is often used for top bike racing, triathlons, downhill racing and e-bikes. The reason for this is the unique forming properties which make it possible to reduce the center section of the spoke and therefore lower the weight, increase the strength, and fatigue resistance as well as flexibility. After reduction, the center section can also be pressed in a mold to form shapes that will improve aerodynamics. It is within this collection you can find one of the world’s best spoke wires. Our research has proven that a better adjusted chemistry will improve fatigue properties. Our A1 and A2 therefore have up to 25% better fatigue properties compared to standard 304 material.

EN | TYPE | Fagersta | C % | Si % | Mn % | Cr % | Ni % | Mo % | N % | TS Nmm2 (ksi) | CWH | Md30 Nohara | PRE | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

VECTOR® A1 | 1.4301 | 302 | R 300.20 | 0.052 | 0.45 | 1.20 | 17.40 | 8.25 | 0.60 | 0.050 | 850-1300 (123-189) | 128 | 4 | 19 |

VECTOR® A2 | 1.4310 | 302Mo | R 300.38 | 0.1 | 1.4 | 1.6 | 17.2 | 8.2 | 0.7 | 0.03 | 1300-1500 (189-218) | 139 | -31 | 20 |

PRE = Cr + 3.1 * Mo + 25 * N

We can control mechanical properties and surface conditions by chosing a specific grade and how we process the wire in production. Following mechanical properties are important for spoke wire:

Tensile strength

High tensile strength is needed. We supply in customized levels from 850-1500 N/mm2 (123-218 ksi).

Forming properties

This is important in order to be able to reduce the spoke diameter in the middle section which will save weight, increase strength, flexibility and fatigue resistance. Straightening, bending and threading properties are also important basic requirements in order to make any type of spoke wire.

Elongation

By testing and calculating CWH and Md30 we can control elongation in relation to tensile strength.

Since spoke wire is in contact with water, corrosion resistance is important.

PRE (Pitting Resistance Equivalent) is a factor comparing properties of different chemistries with regards to pitting and crevice corrosion in corrosive environments. A higher value means better resistance. The materials PRE-value is shown in our steel grade tables. Surface smoothness is also an important factor to prevent corrosion.

Spoke wire is often used in environments where there are high demands with regards to aesthetical properties. It is therefore important that the surface is bright and free from defects. We have developed our own various bright drawing methods which makes it possible for us to offer standard to high demanding Surfaces:

Standard

1.50 – 5.00 mm (.059″ – .394″)

Tolerance

+0/-0.02 (+0/-.001″)

Ovality

Max 50% of the total tolerance range

"*" indicates required fields

MARCEGAGLIA FAGERSTA STAINLESS

P.O. box 508 SE, 73725, Fagersta – Sweden

phone +46 223 455 00

info.fagersta@marcegaglia.com

fagersta.marcegaglia.com

HEADQUARTERS

via Bresciani, 16

46040 Gazoldo degli Ippoliti

Mantova – Italy

phone +39 0376 685 1

info@marcegaglia.com

"*" indicates required fields